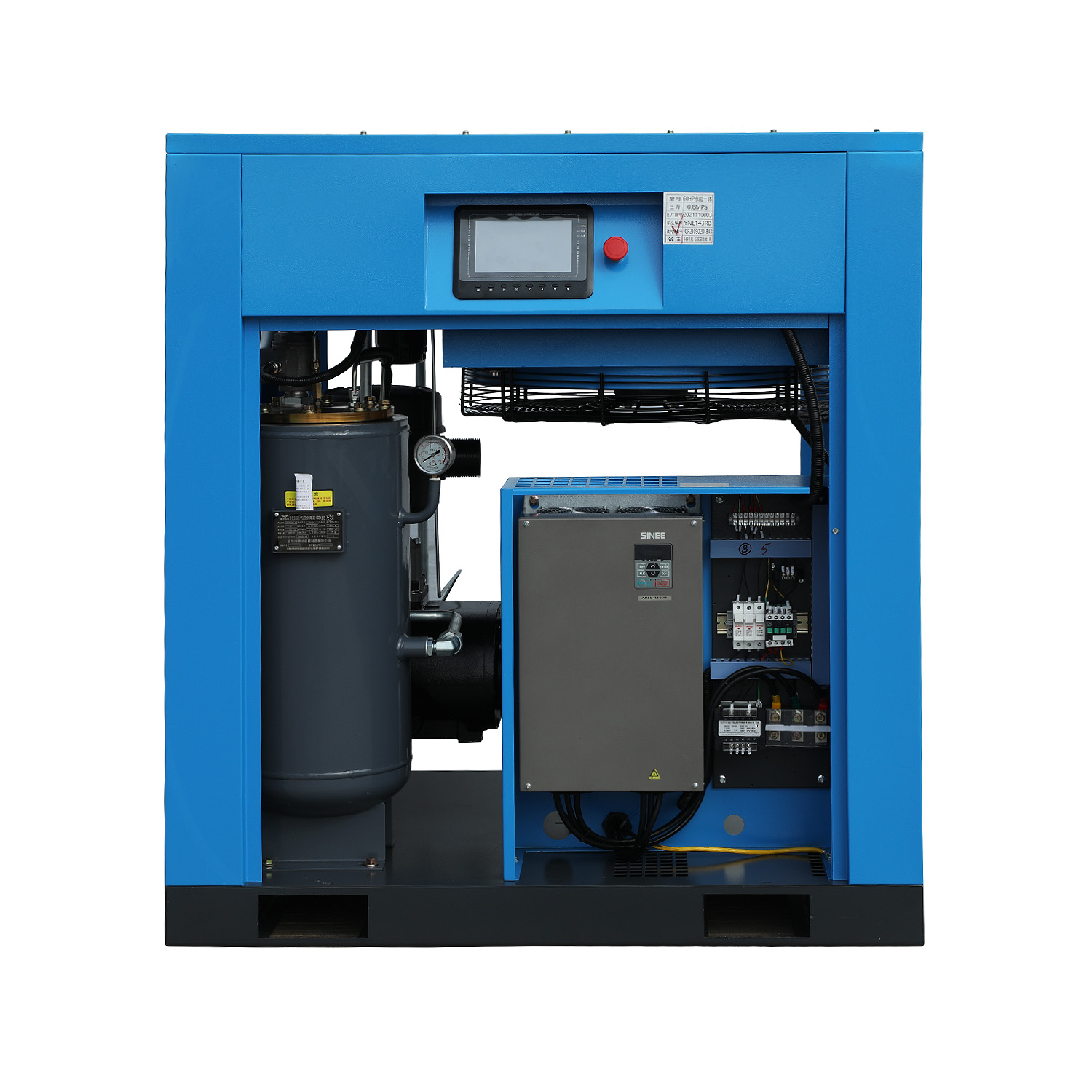

VFD screw air compressor is also called variable frequency drive screw compressor, the type of compressor equipped with an inverter to control the compressor produce compressed air according to customers air demand. VFD compressor is energy-saving than fixed frequency drive screw compressor

Working Power: 7.5~45KW(10~6HP) integrated models,55-250kw (75-350HP) direct drive VFD PM models

Working Pressure: 7/8/10/12.5

Super Premium Efficiency

- ● Oil-cooled motor.

- ● Fully enclosed lP32/54protection.

- ● Reach lE3 efficiency standard.

- ● VSD: variable speed drive.

- ● Optimal cooling for all speeds and ambient conditions.

- ● Bearing free motor requires zero maintenance.

- ● UH series Permanent magnets resist to 180°℃

- ● F grade insulation and B grade temperature rise assessment.

- ● High temperature design prevents demagnetization.

We use proprietary algorithms to adjust compressor speed based on the factory’s changing load demands. This provides the precise air volume and pressure required by our customers, while maximizing energy savings.

Through wide-range variable frequency control, wide-range control, and an emergency stop function, we achieve energy savings regardless of load.

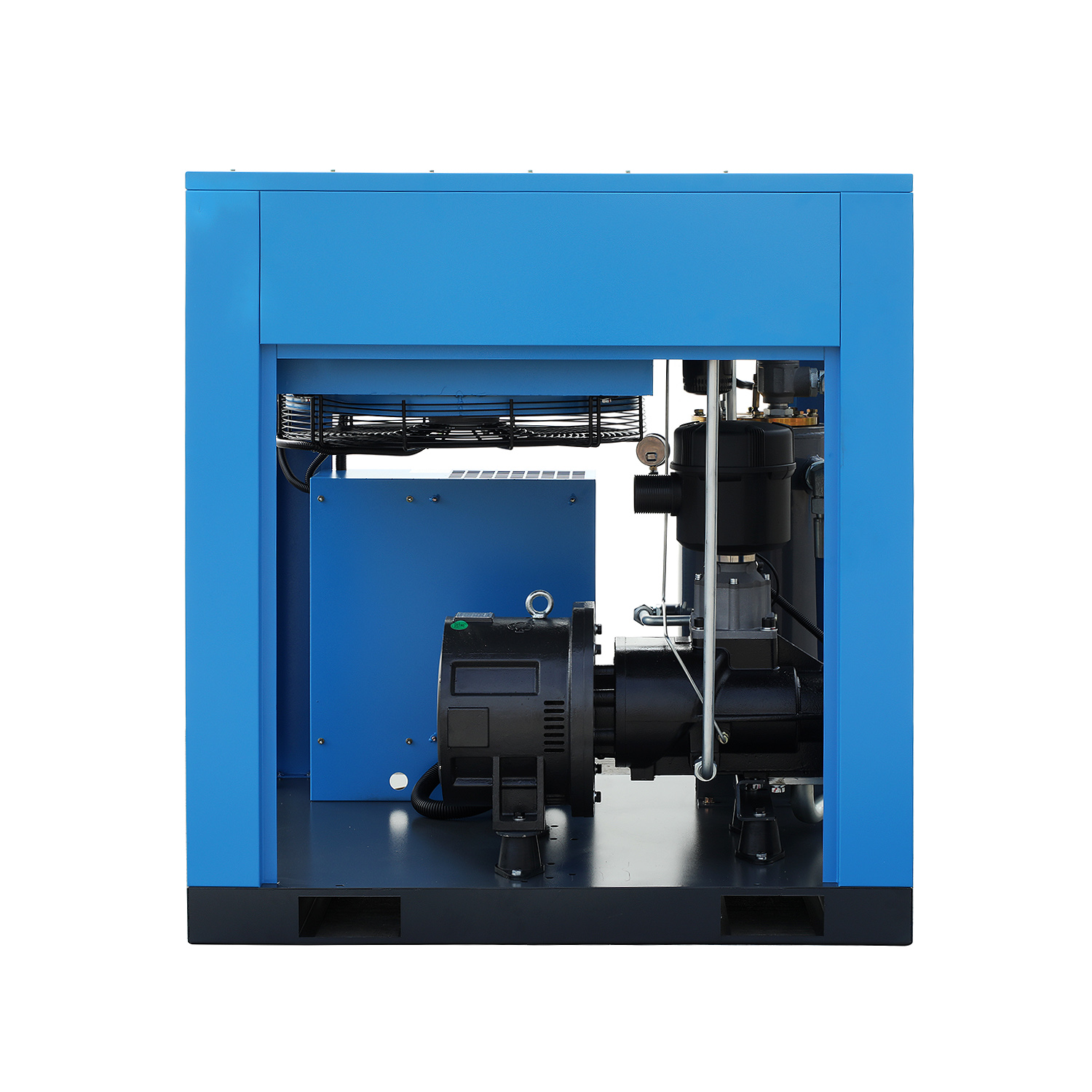

The permanent magnet motor features a double-shell design with an oil passageway between the inner and outer shells. This utilizes the compressor’s own lubrication system to circulate cooling through the oil passageway, eliminating contact with external cooling air and making it ideal for use in dusty environments.

Dual Frequency Conversion System

Constant Pressure Output:

Constant pressure control provides significant energy savings, keeping pressure fluctuations within ±0.01 MPa.

VFD screw air compressor is also called variable frequency drive screw compressor, the type of compressor equipped with an inverter to control the compressor produce compressed air according to customers air demand. VFD compressor is energy-saving than fixed frequency drive screw compressorConstant Temperature Output:

The typical set temperature is 81°C, ensuring optimal lubrication performance while preventing sudden shutdowns caused by high temperatures.

| XZV- series technical parameters: |

| Model |

10A |

15A |

20A |

25A |

30A |

40A |

X50A |

60A |

75A |

| Free air delivery/Discharge air pressure (M3/min/ Mpa) |

1.1/0.7 |

1.65/0.7 |

2.5/0.7 |

3.0/0.7 |

3.7/0.7 |

5.0/0.7 |

6.5/0.7 |

8.0/0.7 |

10.8/0.7 |

| 1.0/0.8 |

1.5/0.8 |

2.3/0.8 |

2.9/0.8 |

3.5/0.8 |

4.8/0.8 |

6.2/0.8 |

7.5/0.8 |

10.2/0.8 |

| 0.9/1.0 |

1.53/1.0 |

2.1/1.0 |

2.7/1.0 |

3.1/1.0 |

4.3/1.0 |

5.6/1.0 |

6.8/1.0 |

9.0/1.0 |

| 0.8/1.25 |

1.1/1.25 |

1.7/1.25 |

2.4/1.25 |

2.7/1.25 |

4.0/1.25 |

5.0/1.25 |

5.6/1.25 |

7.6/1.25 |

| Air supply temperature |

≤ambient temperature +8~`15ºC |

| Motor |

Power (kw/hp) |

7.5/10 |

11/15 |

15/20 |

18.5/25 |

22/30 |

30/40 |

37/50 |

45/60 |

55/75 |

| Start method |

Y-△Starter |

| Voltage (v/hz) |

380V 3PH 50HZ (380V-3PH-60HZ/ 460V- 3PH- 60HZ/ 220V- 3PH-60HZ/ 400V-3PH-50HZ/6000V-3PH-50HZ/other voltagesd customized ) |

| Drive method |

Direct Drive |

| Oil content (PPM) |

≤3 |

| Connector inch |

3/4″ |

3/4″ |

1″ |

1″ |

1″ |

1 1/4″ |

1 1/4″ |

1 1/2″ |

1 1/2″ |

| Noise(Db)±2 |

66 |

68 |

68 |

68 |

68 |

68 |

72 |

72 |

75 |

| Dimension |

length mm |

850 |

1100 |

1100 |

1250 |

1250 |

1250 |

1350 |

1350 |

1800 |

| width mm |

670 |

750 |

750 |

850 |

850 |

850 |

1000 |

1000 |

1230 |

| height mm |

870 |

920 |

920 |

1160 |

1160 |

1160 |

1190 |

1190 |

1570 |

| Weight (kg) |

178 |

260 |

267 |

310 |

396 |

450 |

586 |

593 |

1073 |

|

|

|

|

|

|

|

|

|

|

|

| Model |

100A |

120A |

150A |

175A |

200A |

250A |

300A |

350A |

|

| Free air delivery/Discharge air pressure (M3/min/ Mpa) |

13.4/0.7 |

16.2/0.7 |

21.0/0.7 |

24.5/0.7 |

28.7/0.7 |

32.0/0.7 |

36.0/0.7 |

42.0/0.7 |

|

| 12.6/0.8 |

15.0/0.8 |

19.8/0.8 |

23.2/0.8 |

27.6/0.8 |

30.4/0.8 |

34.3/0.8 |

40.5/0.8 |

|

| 11.2/1.0 |

13.8/1.0 |

17.4/1.0 |

20.5/1.0 |

24.6/1.0 |

27.4/1.0 |

30.2/1.0 |

38.2/1.0 |

|

| 10/1.25 |

12.3/1.25 |

14.8/1.25 |

17.4/1.25 |

21.5/1.25 |

24.8/1.25 |

27.7/1.25 |

34.5/1.25 |

|

| Air supply temperature |

≤ambient temperature +8~`15ºC |

|

| Motor |

Power (kw/hp) |

75/100 |

90/120 |

110/150 |

132/175 |

160/200 |

185/250 |

220/300 |

250/350 |

|

| Start method |

Y-△Starter |

|

| Voltage (v/hz) |

380V 3PH 50HZ (380V-3PH-60HZ/ 460V- 3PH- 60HZ/ 220V- 3PH-60HZ/ 400V-3PH-50HZ/6000V-3PH-50HZ/other voltagesd customized ) |

|

| Drive method |

Direct Drive |

|

| Oil content (PPM) |

≤3 |

|

| Connector inch |

2″ |

2″ |

2 1/4″ |

2 1/2″ |

2 1/2″ |

2 1/2″ |

DN100 |

DN100 |

|

| Noise(Db)±2 |

78 |

85 |

85 |

85 |

88 |

88 |

90 |

90 |

|

| Dimension |

length mm |

1900 |

1900 |

2300 |

2300 |

2650 |

2650 |

3300 |

3300 |

|

| width mm |

1230 |

1230 |

1470 |

1470 |

1650 |

1650 |

2100 |

2100 |

|

| height mm |

1570 |

1570 |

1840 |

1840 |

2045 |

2045 |

2045 |

2190 |

|

| Weight (kg) |

1171 |

1327 |

1801 |

1848 |

2400 |

2600 |

3100 |

3300 |

|

Advantages:

1. The compressor was energy-saving, will save electric cost for the user.

2. The price of the compressor is fair, not expensive.

3. The compressor has enough air discharge, meets user’s compressed air need.

FAQ:

1.How about the quality of your compressor?

good-quality with 21 years experience.

2. Could you send the machine to overseas?

Yes, of course !please tell me your port.

3. Could you make a certificate of original for me?

Yes, I will make based on your country .

4. What material would you use to pack your machine?

We will use a wooden to pack our compressor.

5. Could you take a photo of the machine before the transportation?

OK, I will take videos and photos for you!

6. Which kinds of motor do your compressor use?

Our compressor uses PM motor and inverter.