VFD PM screw air compressor

-

110Kw/150Hp Two-Stage Rotary Screw Air Compressor Permanent Magnetic Variable Frequency 380V Air Cooled

motor with high efficiency, Remarkable energy-saving effect

1. At rated speed point, permanent magnet motor efficiency is higher Than ordinary motors.

2. Under low motor speed, permanent magnet motor can still keep high Motor efficiency. If the gas consumption less, it still keeps extremely High efficiency. Compared with common frequency conversion

Motor, the motor efficiency appears obvious gap and the air Compressor has effective energy saving

Small volume, low noise

It has the integrated structure, configuration of high efficiency Permanent magnet motor, small size, saving space, easy disassembly. Deloying efficient permanent magnet variable frequency controllor, it

Can change the speed of the permanent magnet motor according to The exhaust volume, it will achieve lower operation noise than ordinary Ones.

a. Permanent magnet motor has high performance NdFeB permanent Magnet, 120 º Cwithout loss of excitation, and service life of over 15 Years.

b. Stator coil adopts special inverter corona resistant enamelled wire. Insulation performance and longer service life.

c. Realizing soft start, the motor current will not exceed the full load Current during operation, and greatly reduce the impact on network Equipment, no damage to electrical equipment.OSG-EZV series permanent magnet compressor

Energy-saving advantages:Condition energy saving:

1: The permanent magnet motor remains high efficiency at low speeds, ensuring Obvious energy-saving advantages in small air volume.

2: Frequency range from 0%-100% (common conversion from 60%-100%)

3: Compared with the fixed speed compressor, energy saving 22%-40%

4: Compared with the common inverter compressor, energy saving 5%-15%

5: System volume fluctuations larger, then energy-saving effect more obviously.

6: Energy saving system of unloading (inverter):

According to the stationary air compressors in gas consumption fluctuation, it has the unloading time, then the air compressor idling but also need 45% of the Electricity, but the permanent-magnet frequency air compressor will control for Inverter, no unloading and no waste. If the air compressor units become larger,

Energy saves more. Save the wasted electric energy by pressure control bandwidth (energy saving):

Fixed compressor must set a minimum control pressure for the 1Barg band (i. E. Air

Compressor limits) to avoid the impact on the unit and the power grid. Several

Machines must use together with a pressure gradient, more wide pressure, while the

OSG permanent-magnet variable-frequency Air compressor series is inverter control,

Unlimited stop, no need to set pressure, but a pressure point on the line. The pressure

Of each 0.14Barg bandwidth, the system can save energy 1%.Energy saving startup (inverter):

Air compressor’ s starting current is 3-6 times of the rated current, the frequently Start will waste a lot of energy, and frequency conversion type has no frequent Starting and stopping, but soft start. The maximum current does not exceed the Rated working current, no energy waste. At the same time also greatly reduce the Impact on network equipment, and no damage to electrical equipment OSG company has obtained a compressor production license(certificate NO: XK06-010-00597), has obtained a quality system Certificate and general machinery certificate. Product design,Manufacturing processes are strict in accordance with ISO9001: 2008 quality system standardsProfessional service

After-sale service is always one of the most concerned question, and

after-sale service in time is the key. We have Professional after sale

service engineers and complete spare parts. The following branches

serve every customer to provide timely and professional service and

technical training.Adequate supply of resources

Use OSG genuine spare parts and consumables is the basic

guarantee for air compressor running long. We have the normal and

efficient operation, also plenty of spare parts and consumables

reserve, ready to meet the needs of customers.Product quality guarantee

High quality products are the core foundation of business operation. Any product from raw material

purchasing, outsourcing parts processing to the process after the performance and operation of strict

tests ensure the machines of high quality.

Application field

Textile, medical, pharmaceutical materials, power, electronic, spraying,

tobacco, instruments, food processing, feed processing, machinery

processing, etc. -

Cheap 7.5-132 KW Frequency Inverter PM VSD Rotary Screw Air Compressor

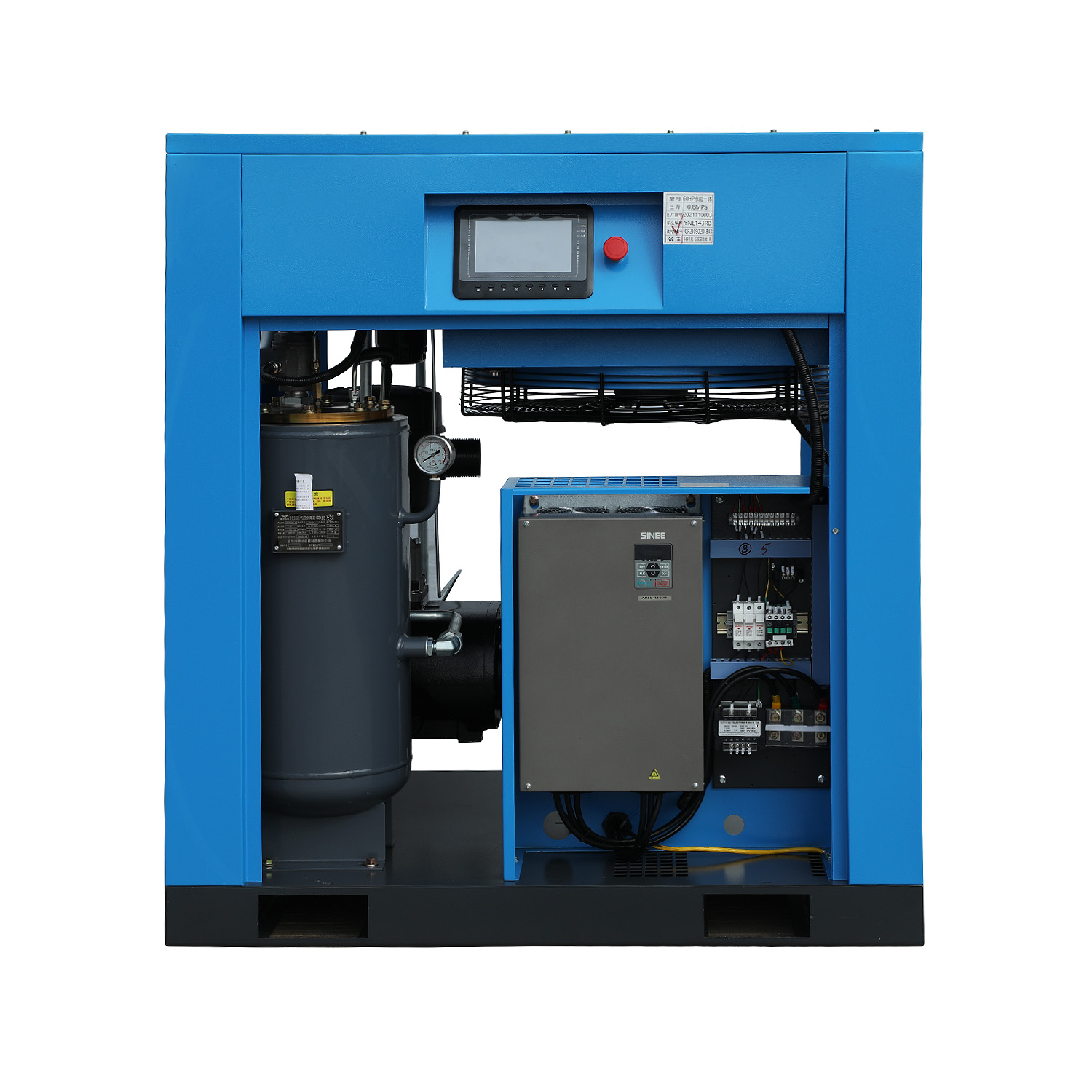

Permanent Magnet Motor (PM Motor) – Offers IE4/IE5 ultra-high efficiency, significantly lowering power consumption compared to traditional induction motors.Integrated Variable Frequency Drive (VFD) – Automatically adjusts motor speed to match air demand, eliminating energy waste from unloading cycles.Low Noise & Vibration – Optimized screw rotor design and soundproof enclosure ensure quiet operation (as low as 65 dB).Compact & Space-Saving Design – Fully integrated unit with built-in cooling system, reducing installation footprint. Smart Control System – User-friendly LCD touchscreen with real-time monitoring, fault alerts, and remote control capability.

High-Quality Components – Premium bearings, corrosion-resistant rotors, and efficient filtration ensure long service life and minimal downtime.

Key Features:Ideal for manufacturing, automotive, textiles, food & beverage, pharmaceuticals, and electronics industries, where stable air supply and energy efficiency are critical.Why Choose Our Compressor?

Key Features:Ideal for manufacturing, automotive, textiles, food & beverage, pharmaceuticals, and electronics industries, where stable air supply and energy efficiency are critical.Why Choose Our Compressor?

30-40% Energy Savings – Reduces operational costs with superior efficiency.

Maintenance-Free Permanent Magnet Motor – No brushes or slip rings, ensuring long-term reliability. Plug-and-Play Installation – Pre-assembled design for quick setup.

5-Year Motor Warranty – Confidence in quality and durability.

Technical SpecificationsPermanent Magnet Motor (PM Motor) – Offers IE4/IE5 ultra-high efficiency, significantly lowering power consumption compared to traditional induction motors.

Technical SpecificationsPermanent Magnet Motor (PM Motor) – Offers IE4/IE5 ultra-high efficiency, significantly lowering power consumption compared to traditional induction motors.

Integrated Variable Frequency Drive (VFD) – Automatically adjusts motor speed to match air demand, eliminating energy waste from unloading cycles.

Low Noise & Vibration – Optimized screw rotor design and soundproof enclosure ensure quiet operation (as low as 65 dB).

Compact & Space-Saving Design – Fully integrated unit with built-in cooling system, reducing installation footprint.

Smart Control System – User-friendly LCD touchscreen with real-time monitoring, fault alerts, and remote control capability.

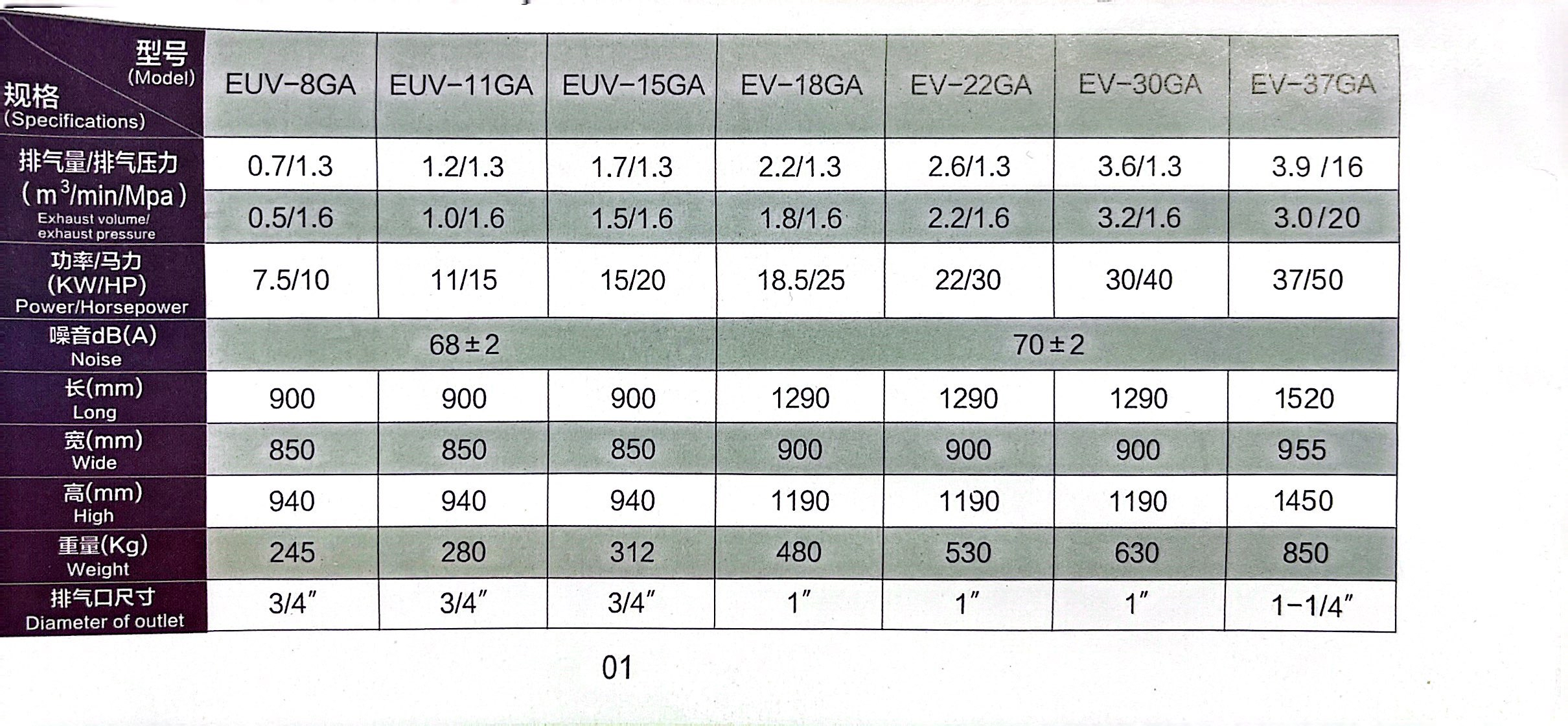

High-Quality Components – Premium bearings, corrosion-resistant rotors, and efficient filtration ensure long service life and minimal downtime.XZV-8AXZV-11AXZV-15AXZV-18AXZV-22AXZV-30AXZV-37AXZV-45A/XZV-55AXZV-75A1.1/0.71.8/0.72.5/0.73.0/0.73.7/0.75.0/0.76.5/0.77.4/0.710.0/0.713.4/0.71.0/0.81.7/0.82.3/0.82.9/0.83.5/0.84.8/0.86.2/0.87.0/0.89.6/0.812.6/0.80.9/1.01.5/1.02.0/1.02.7/1.03.1/1.04.3/1.05.6/1.06.2/1.08.5/1.011.2/1.00.7/1.31.2/1.31.7/1.32.2/1.32.6/1.33.6/1.34.5/1.35.5/1.37.2/1.39.8/1.3≤ambient temperature +8~`15ºC7.5/1011/1515/2018.5/2522/3030/4037/5045/6055/7575/100VSD Starter380V 3PH 50HZ(380V-3PH-60HZ/ 460V- 3PH- 60HZ/ 220V- 3PH-60HZ/ 400V-3PH-50HZ/6000V-3PH-50HZ/other voltagesd customized )Coupling transmission≤33/4″3/4″1″1″1″11/4″11/4″1 1/2″1 1/2″2″666868686868727275789001100110010601060106015001500180019007007507508208208201000100012301230930100010001220122012201290129015701570140200210235296336443466834917After Sales ServiceStandard Warranty: 12 months.

Global Support: 24/7 technical assistance and spare parts supply.

Training: On-site or remote operation/maintenance training. -

Manufacturer – Factory Direct Price – 75KW Screw Air Compressor Supplier

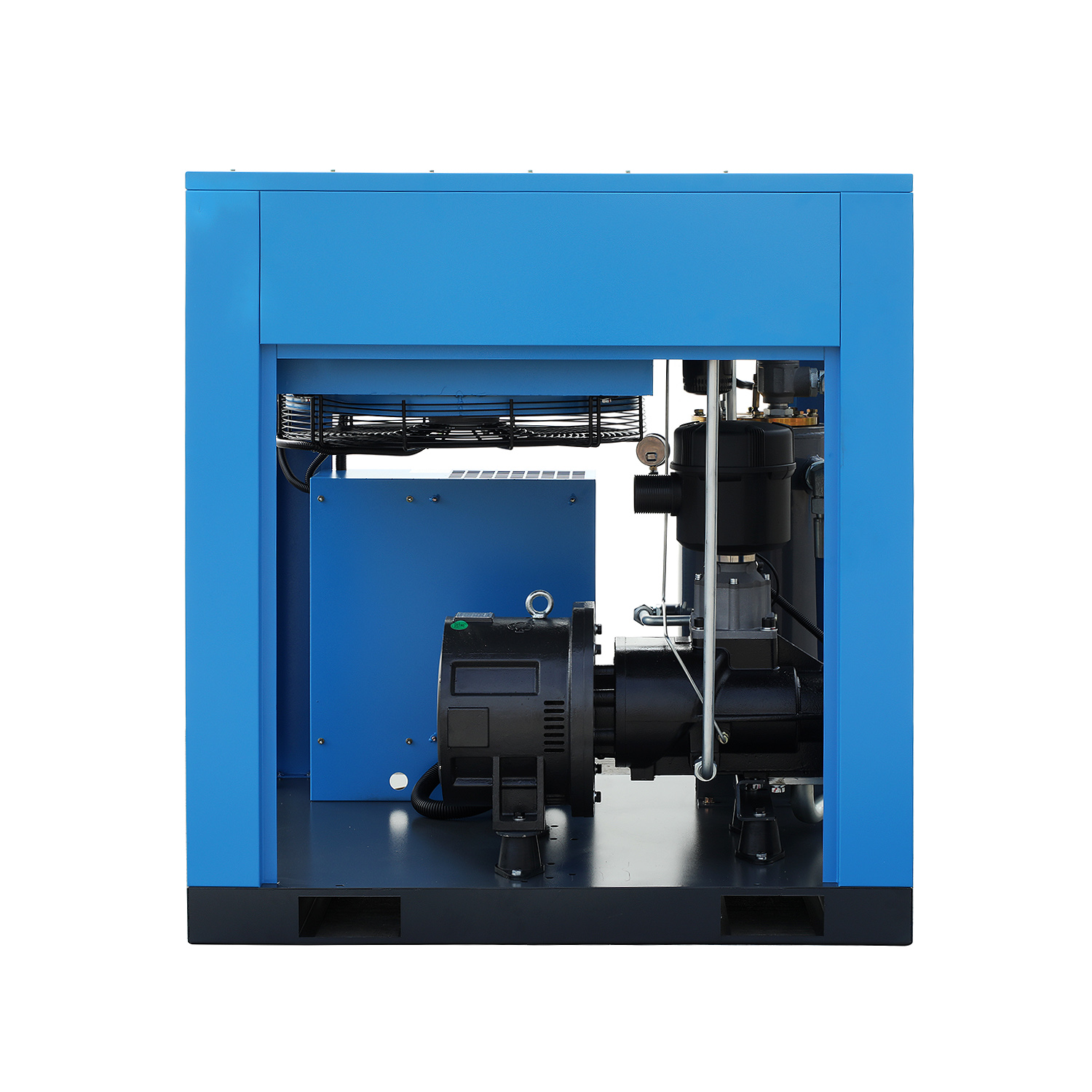

The OSG single-stage, frequency-standard screw air compressor features low energy consumption, high capacity, and superior design and manufacturing. It reduces daily maintenance requirements, perfectly replacing reciprocating air compressors, and offers intelligent remote control, simplifying complex operations.

Screw Air Compressor Features:

■ 1:1 direct drive for low noise and energy consumption, effectively protecting the motor torque.

■ High-quality sound-absorbing materials and enclosure ensure operating noise remains within ideal levels, providing a quiet and comfortable working environment.

■ Fewer moving parts lead to stable performance and low maintenance costs.

■ Compact design with a sleek and elegant appearance, saving space.

■ Removable air duct cover for easy maintenance.

■ Intelligent control system for simple operation. Screw Compressor Control and Electrical System:

■ RS485 communication for data collection and integration into the user’s central control panel for monitoring.

■ Intelligent controller dynamically adjusts control accuracy for precise torque control.

■ Real-time display of operating parameters, maintenance alerts, energy management, and data analysis via mobile phone or computer.

-

VFD screw air compressor 0.7-1.25mpa Energy Saving up to 30%

VFD screw air compressor is also called variable frequency drive screw compressor, the type of compressor equipped with an inverter to control the compressor produce compressed air according to customers air demand. VFD compressor is energy-saving than fixed frequency drive screw compressor

Working Power: 7.5~45KW(10~6HP) integrated models,55-250kw (75-350HP) direct drive VFD PM models

Working Pressure: 7/8/10/12.5Super Premium Efficiency

- ● Oil-cooled motor.

- ● Fully enclosed lP32/54protection.

- ● Reach lE3 efficiency standard.

- ● VSD: variable speed drive.

- ● Optimal cooling for all speeds and ambient conditions.

- ● Bearing free motor requires zero maintenance.

- ● UH series Permanent magnets resist to 180°℃

- ● F grade insulation and B grade temperature rise assessment.

- ● High temperature design prevents demagnetization.

We use proprietary algorithms to adjust compressor speed based on the factory’s changing load demands. This provides the precise air volume and pressure required by our customers, while maximizing energy savings.

Through wide-range variable frequency control, wide-range control, and an emergency stop function, we achieve energy savings regardless of load.

The permanent magnet motor features a double-shell design with an oil passageway between the inner and outer shells. This utilizes the compressor’s own lubrication system to circulate cooling through the oil passageway, eliminating contact with external cooling air and making it ideal for use in dusty environments.

Dual Frequency Conversion System

Constant Pressure Output:

Constant pressure control provides significant energy savings, keeping pressure fluctuations within ±0.01 MPa.VFD screw air compressor is also called variable frequency drive screw compressor, the type of compressor equipped with an inverter to control the compressor produce compressed air according to customers air demand. VFD compressor is energy-saving than fixed frequency drive screw compressorConstant Temperature Output:

The typical set temperature is 81°C, ensuring optimal lubrication performance while preventing sudden shutdowns caused by high temperatures.XZV- series technical parameters: Model 10A 15A 20A 25A 30A 40A X50A 60A 75A Free air delivery/Discharge air pressure (M3/min/ Mpa) 1.1/0.7 1.65/0.7 2.5/0.7 3.0/0.7 3.7/0.7 5.0/0.7 6.5/0.7 8.0/0.7 10.8/0.7 1.0/0.8 1.5/0.8 2.3/0.8 2.9/0.8 3.5/0.8 4.8/0.8 6.2/0.8 7.5/0.8 10.2/0.8 0.9/1.0 1.53/1.0 2.1/1.0 2.7/1.0 3.1/1.0 4.3/1.0 5.6/1.0 6.8/1.0 9.0/1.0 0.8/1.25 1.1/1.25 1.7/1.25 2.4/1.25 2.7/1.25 4.0/1.25 5.0/1.25 5.6/1.25 7.6/1.25 Air supply temperature ≤ambient temperature +8~`15ºC Motor Power (kw/hp) 7.5/10 11/15 15/20 18.5/25 22/30 30/40 37/50 45/60 55/75 Start method Y-△Starter Voltage (v/hz) 380V 3PH 50HZ (380V-3PH-60HZ/ 460V- 3PH- 60HZ/ 220V- 3PH-60HZ/ 400V-3PH-50HZ/6000V-3PH-50HZ/other voltagesd customized ) Drive method Direct Drive Oil content (PPM) ≤3 Connector inch 3/4″ 3/4″ 1″ 1″ 1″ 1 1/4″ 1 1/4″ 1 1/2″ 1 1/2″ Noise(Db)±2 66 68 68 68 68 68 72 72 75 Dimension length mm 850 1100 1100 1250 1250 1250 1350 1350 1800 width mm 670 750 750 850 850 850 1000 1000 1230 height mm 870 920 920 1160 1160 1160 1190 1190 1570 Weight (kg) 178 260 267 310 396 450 586 593 1073 Model 100A 120A 150A 175A 200A 250A 300A 350A Free air delivery/Discharge air pressure (M3/min/ Mpa) 13.4/0.7 16.2/0.7 21.0/0.7 24.5/0.7 28.7/0.7 32.0/0.7 36.0/0.7 42.0/0.7 12.6/0.8 15.0/0.8 19.8/0.8 23.2/0.8 27.6/0.8 30.4/0.8 34.3/0.8 40.5/0.8 11.2/1.0 13.8/1.0 17.4/1.0 20.5/1.0 24.6/1.0 27.4/1.0 30.2/1.0 38.2/1.0 10/1.25 12.3/1.25 14.8/1.25 17.4/1.25 21.5/1.25 24.8/1.25 27.7/1.25 34.5/1.25 Air supply temperature ≤ambient temperature +8~`15ºC Motor Power (kw/hp) 75/100 90/120 110/150 132/175 160/200 185/250 220/300 250/350 Start method Y-△Starter Voltage (v/hz) 380V 3PH 50HZ (380V-3PH-60HZ/ 460V- 3PH- 60HZ/ 220V- 3PH-60HZ/ 400V-3PH-50HZ/6000V-3PH-50HZ/other voltagesd customized ) Drive method Direct Drive Oil content (PPM) ≤3 Connector inch 2″ 2″ 2 1/4″ 2 1/2″ 2 1/2″ 2 1/2″ DN100 DN100 Noise(Db)±2 78 85 85 85 88 88 90 90 Dimension length mm 1900 1900 2300 2300 2650 2650 3300 3300 width mm 1230 1230 1470 1470 1650 1650 2100 2100 height mm 1570 1570 1840 1840 2045 2045 2045 2190 Weight (kg) 1171 1327 1801 1848 2400 2600 3100 3300 Advantages:

1. The compressor was energy-saving, will save electric cost for the user.

2. The price of the compressor is fair, not expensive.

3. The compressor has enough air discharge, meets user’s compressed air need.FAQ:

1.How about the quality of your compressor?

good-quality with 21 years experience.2. Could you send the machine to overseas?

Yes, of course !please tell me your port.3. Could you make a certificate of original for me?

Yes, I will make based on your country .4. What material would you use to pack your machine?

We will use a wooden to pack our compressor.5. Could you take a photo of the machine before the transportation?

OK, I will take videos and photos for you!6. Which kinds of motor do your compressor use?

Our compressor uses PM motor and inverter. -

Low Noise Industrial High Efficiency 10HP 15HP 20HP 30HP 100HP Rotary Pm VSD Screw Type Air Compressor

VFD screw air compressor is also called variable frequency drive screw compressor, the type of compressor equipped with an inverter to control the compressor produce compressed air according to customers air demand. VFD compressor is energy-saving than fixed frequency drive screw compressor

Working Power: 7.5~45KW(10~6HP) integrated models,55-250kw (75-350HP) direct drive VFD PM models

Working Pressure: 7/8/10/12.5Super Premium Efficiency

- ● Oil-cooled motor.

- ● Fully enclosed lP32/54protection.

- ● Reach lE3 efficiency standard.

- ● VSD: variable speed drive.

- ● Optimal cooling for all speeds and ambient conditions.

- ● Bearing free motor requires zero maintenance.

- ● UH series Permanent magnets resist to 180°℃

- ● F grade insulation and B grade temperature rise assessment.

- ● High temperature design prevents demagnetization.

We use proprietary algorithms to adjust compressor speed based on the factory’s changing load demands. This provides the precise air volume and pressure required by our customers, while maximizing energy savings.

Through wide-range variable frequency control, wide-range control, and an emergency stop function, we achieve energy savings regardless of load.

The permanent magnet motor features a double-shell design with an oil passageway between the inner and outer shells. This utilizes the compressor’s own lubrication system to circulate cooling through the oil passageway, eliminating contact with external cooling air and making it ideal for use in dusty environments.

Dual Frequency Conversion System

Constant Pressure Output:

Constant pressure control provides significant energy savings, keeping pressure fluctuations within ±0.01 MPa.VFD screw air compressor is also called variable frequency drive screw compressor, the type of compressor equipped with an inverter to control the compressor produce compressed air according to customers air demand. VFD compressor is energy-saving than fixed frequency drive screw compressorConstant Temperature Output:

The typical set temperature is 81°C, ensuring optimal lubrication performance while preventing sudden shutdowns caused by high temperatures.XZV- series technical parameters: Model 10A 15A 20A 25A 30A 40A X50A 60A 75A Free air delivery/Discharge air pressure (M3/min/ Mpa) 1.1/0.7 1.65/0.7 2.5/0.7 3.0/0.7 3.7/0.7 5.0/0.7 6.5/0.7 8.0/0.7 10.8/0.7 1.0/0.8 1.5/0.8 2.3/0.8 2.9/0.8 3.5/0.8 4.8/0.8 6.2/0.8 7.5/0.8 10.2/0.8 0.9/1.0 1.53/1.0 2.1/1.0 2.7/1.0 3.1/1.0 4.3/1.0 5.6/1.0 6.8/1.0 9.0/1.0 0.8/1.25 1.1/1.25 1.7/1.25 2.4/1.25 2.7/1.25 4.0/1.25 5.0/1.25 5.6/1.25 7.6/1.25 Air supply temperature ≤ambient temperature +8~`15ºC Motor Power (kw/hp) 7.5/10 11/15 15/20 18.5/25 22/30 30/40 37/50 45/60 55/75 Start method Y-△Starter Voltage (v/hz) 380V 3PH 50HZ (380V-3PH-60HZ/ 460V- 3PH- 60HZ/ 220V- 3PH-60HZ/ 400V-3PH-50HZ/6000V-3PH-50HZ/other voltagesd customized ) Drive method Direct Drive Oil content (PPM) ≤3 Connector inch 3/4″ 3/4″ 1″ 1″ 1″ 1 1/4″ 1 1/4″ 1 1/2″ 1 1/2″ Noise(Db)±2 66 68 68 68 68 68 72 72 75 Dimension length mm 850 1100 1100 1250 1250 1250 1350 1350 1800 width mm 670 750 750 850 850 850 1000 1000 1230 height mm 870 920 920 1160 1160 1160 1190 1190 1570 Weight (kg) 178 260 267 310 396 450 586 593 1073 Model 100A 120A 150A 175A 200A 250A 300A 350A Free air delivery/Discharge air pressure (M3/min/ Mpa) 13.4/0.7 16.2/0.7 21.0/0.7 24.5/0.7 28.7/0.7 32.0/0.7 36.0/0.7 42.0/0.7 12.6/0.8 15.0/0.8 19.8/0.8 23.2/0.8 27.6/0.8 30.4/0.8 34.3/0.8 40.5/0.8 11.2/1.0 13.8/1.0 17.4/1.0 20.5/1.0 24.6/1.0 27.4/1.0 30.2/1.0 38.2/1.0 10/1.25 12.3/1.25 14.8/1.25 17.4/1.25 21.5/1.25 24.8/1.25 27.7/1.25 34.5/1.25 Air supply temperature ≤ambient temperature +8~`15ºC Motor Power (kw/hp) 75/100 90/120 110/150 132/175 160/200 185/250 220/300 250/350 Start method Y-△Starter Voltage (v/hz) 380V 3PH 50HZ (380V-3PH-60HZ/ 460V- 3PH- 60HZ/ 220V- 3PH-60HZ/ 400V-3PH-50HZ/6000V-3PH-50HZ/other voltagesd customized ) Drive method Direct Drive Oil content (PPM) ≤3 Connector inch 2″ 2″ 2 1/4″ 2 1/2″ 2 1/2″ 2 1/2″ DN100 DN100 Noise(Db)±2 78 85 85 85 88 88 90 90 Dimension length mm 1900 1900 2300 2300 2650 2650 3300 3300 width mm 1230 1230 1470 1470 1650 1650 2100 2100 height mm 1570 1570 1840 1840 2045 2045 2045 2190 Weight (kg) 1171 1327 1801 1848 2400 2600 3100 3300 Advantages:

1. The compressor was energy-saving, will save electric cost for the user.

2. The price of the compressor is fair, not expensive.

3. The compressor has enough air discharge, meets user’s compressed air need.FAQ:

1.How about the quality of your compressor?

good-quality with 21 years experience.2. Could you send the machine to overseas?

Yes, of course !please tell me your port.3. Could you make a certificate of original for me?

Yes, I will make based on your country .4. What material would you use to pack your machine?

We will use a wooden to pack our compressor.5. Could you take a photo of the machine before the transportation?

OK, I will take videos and photos for you!6. Which kinds of motor do your compressor use?

Our compressor uses PM motor and inverter. -

15kw/20HP Integrated Pm Frequency Conversion VSD Screw Air Compressor

15kw/20HP Integrated Pm Frequency Conversion VSD Screw Air Compressor

Energy-Efficient & Reliable Performance

Our 15kW Permanent Magnet Variable Frequency Integrated Screw Air Compressor combines advanced permanent magnet motor technology with a fully integrated variable frequency drive (VFD) system to deliver exceptional energy savings, stable performance, and low maintenance costs. Designed for industrial and commercial applications, this compressor ensures high efficiency, reduced energy consumption, and quiet operation.SpecificationPermanent Magnet Motor (PM Motor) – Offers IE4/IE5 ultra-high efficiency, significantly lowering power consumption compared to traditional induction motors.Integrated Variable Frequency Drive (VFD) – Automatically adjusts motor speed to match air demand, eliminating energy waste from unloading cycles.Low Noise & Vibration – Optimized screw rotor design and soundproof enclosure ensure quiet operation (as low as 65 dB).Compact & Space-Saving Design – Fully integrated unit with built-in cooling system, reducing installation footprint. Smart Control System – User-friendly LCD touchscreen with real-time monitoring, fault alerts, and remote control capability.

High-Quality Components – Premium bearings, corrosion-resistant rotors, and efficient filtration ensure long service life and minimal downtime.Key FeatureIdeal for manufacturing, automotive, textiles, food & beverage, pharmaceuticals, and electronics industries, where stable air supply and energy efficiency are critical.Why Choose Our Compressor?

30-40% Energy Savings – Reduces operational costs with superior efficiency.

Maintenance-Free Permanent Magnet Motor – No brushes or slip rings, ensuring long-term reliability. Plug-and-Play Installation – Pre-assembled design for quick setup.

1-Year Motor Warranty – Confidence in quality and durability.Technical SpecificationsPermanent Magnet Motor (PM Motor) – Offers IE4/IE5 ultra-high efficiency, significantly lowering power consumption compared to traditional induction motors.

Integrated Variable Frequency Drive (VFD) – Automatically adjusts motor speed to match air demand, eliminating energy waste from unloading cycles.

Low Noise & Vibration – Optimized screw rotor design and soundproof enclosure ensure quiet operation (as low as 65 dB).

Compact & Space-Saving Design – Fully integrated unit with built-in cooling system, reducing installation footprint.

Smart Control System – User-friendly LCD touchscreen with real-time monitoring, fault alerts, and remote control capability.

High-Quality Components – Premium bearings, corrosion-resistant rotors, and efficient filtration ensure long service life and minimal downtimeXZV-8A XZV-11A XZV-15A XZV-18A XZV-22A XZV-30A XZV-37A XZV-45A/ XZV-55A XZV-75A 1.1/0.7 1.8/0.7 2.5/0.7 3.0/0.7 3.7/0.7 5.0/0.7 6.5/0.7 7.4/0.7 10.0/0.7 13.4/0.7 1.0/0.8 1.7/0.8 2.3/0.8 2.9/0.8 3.5/0.8 4.8/0.8 6.2/0.8 7.0/0.8 9.6/0.8 12.6/0.8 0.9/1.0 1.5/1.0 2.0/1.0 2.7/1.0 3.1/1.0 4.3/1.0 5.6/1.0 6.2/1.0 8.5/1.0 11.2/1.0 0.7/1.3 1.2/1.3 1.7/1.3 2.2/1.3 2.6/1.3 3.6/1.3 4.5/1.3 5.5/1.3 7.2/1.3 9.8/1.3 ≤ambient temperature +8~`15ºC 7.5/10 11/15 15/20 18.5/25 22/30 30/40 37/50 45/60 55/75 75/100 VSD Starter 380V 3PH 50HZ(380V-3PH-60HZ/ 460V- 3PH- 60HZ/ 220V- 3PH-60HZ/ 400V-3PH-50HZ/6000V-3PH-50HZ/other voltagesd customized ) Coupling transmission ≤3 3/4″ 3/4″ 1″ 1″ 1″ 11/4″ 11/4″ 1 1/2″ 1 1/2″ 2″ 66 68 68 68 68 68 72 72 75 78 900 1100 1100 1060 1060 1060 1500 1500 1800 1900 700 750 750 820 820 820 1000 1000 1230 1230 930 1000 1000 1220 1220 1220 1290 1290 1570 1570 140 200 210 235 296 336 443 466 834 917 After Sales Service

Standard Warranty: 12 months.

Global Support: 24/7 technical assistance and spare parts supply.

Training: On-site or remote operation/maintenance training.Other products

Fixed Speed Screw Air Compressor

VFD PM Screw Air Compressor

Integrated Screw Air Compressor

Oil Free Screw Air Compressor

Two Stage Screw Air Compressor

Air Dryer

Scroll Air Compressor

Oil Free Screw Blower

Spare Parts

Low Pressure Screw Air

Compressor

Portable Screw Air Compressor

Screw /Rotary Vacuum Pump -

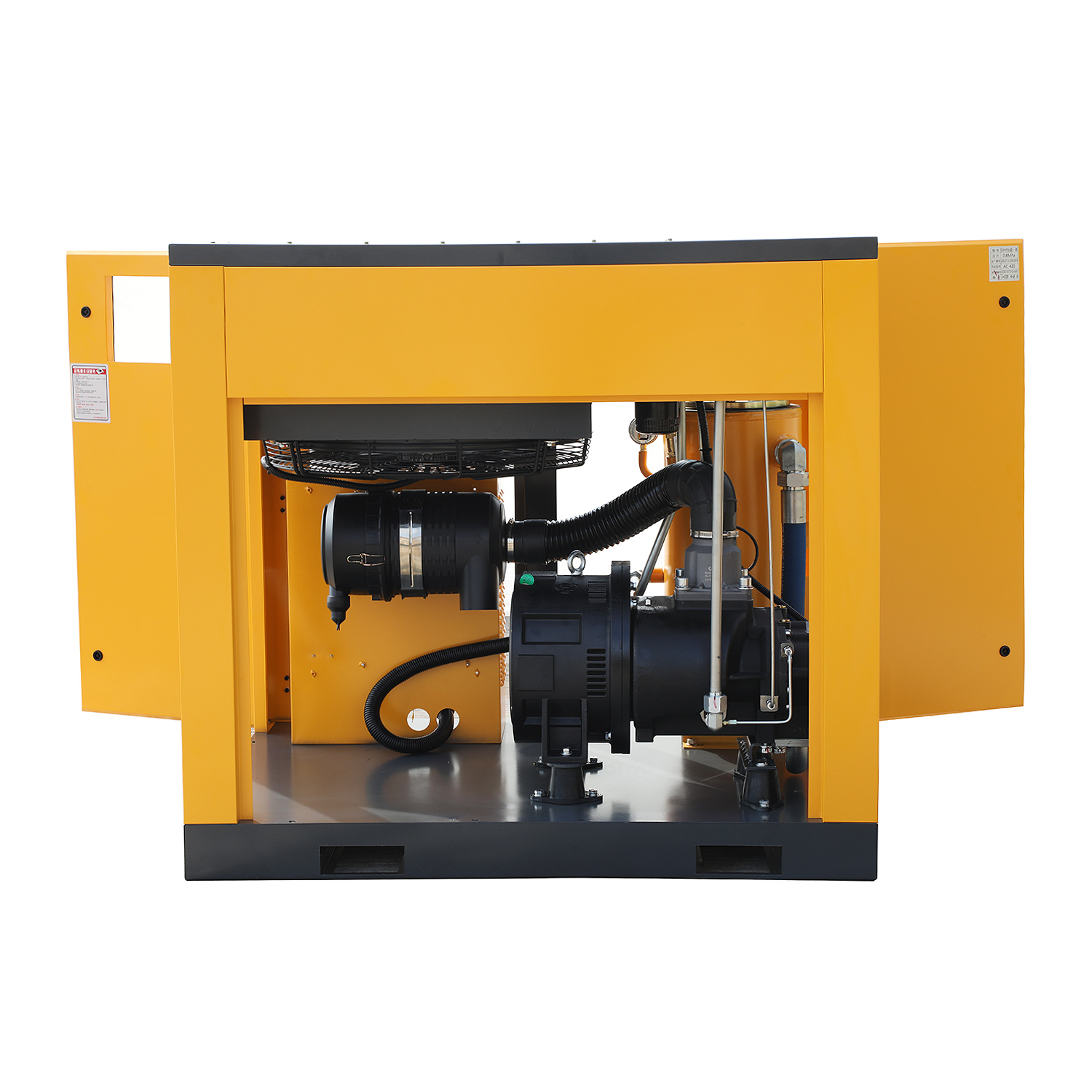

Oil Cooled Screw Air Compressor 55kw 75hp Industrial Air Compressor Rotary Air Compressor

Oil Cooled Screw Air Compressor 55kw 75hp Industrial Air Compressor Rotary Air Compressor Advantages and features New generation appearance design, new structure, stable quality. Coaxial transmission mode is adopted, with higher transmission efficiency and zero transmission efficiency loss. IE5 permanent magnet variable frequency motor is adopted, and the speed can be freely changed according to customer needs. Fully sealed liquid-cooled motor housing, IP65 protection factor. The suspended coaxial direct-connected integrated structure can minimize mechanical loss, ensure the life of the motor, improve transmission efficiency, and reduce floor space with a compact design. Frequency conversion controller: It uses frequency conversion to provide stable pressure and gas conditions suitable for customers. Professional heat dissipation design can operate at an ambient temperature of 50°C, automatically adjust the output rating according to the temperature rise condition, and maintain the inverter to work continuously and efficiently. IP65 liquid-cooled permanent magnet motor The IE5 liquid-cooled permanent magnet motor and IP65 fully sealed protection fully protect the safety of the permanent magnet motor, so you don’t have to worry about the reliability of the motor. Jaguar aftercooler: The high-efficiency cooler has a significant cooling effect; even in harsh operating environments such as high temperature and high humidity, it can ensure the normal operation of the air compressor. Heavy-duty air filter: The unique air intake box system prevents dust from entering the system; it filters fine particles in the air to ensure the quality of the air entering the head and extend the life of the main engine. Application scope: Widely used in energy industry, textile manufacturing industry, machinery manufacturing industry, chemical manufacturing industry and other industries. Ensure reliable production and manufacturing operations and achieve safe, reliable and stable industrial production.

-

11KW 15HP VSD PM/VFD PM Integrated Screw Air Compressor Industrial Air Compressor

1. Energy saving 50% on average by permanent Magnet Motor VSD screw air compressor .

2.high volume,high efficiency.

3.Permanent magnetic electric motor 100% transmission

4.Intelligent touch screen control panel

5.Unique design with inverter to protect from short phase, phase short circuit, ground short circuit, over current, over voltage, under voltage, overload, overheating, motor thermal protections etc.

-

15KW 20HP VSD PM/VFD PM Integrated Screw Air Compressor Industrial Air Compressor

1. Energy saving 50% on average by permanent Magnet Motor VSD screw air compressor .

2.high volume,high efficiency.

3.Permanent magnetic electric motor 100% transmission

4.Intelligent touch screen control panel

5.Unique design with inverter to protect from short phase, phase short circuit, ground short circuit, over current, over voltage, under voltage, overload, overheating, motor thermal protections etc.

-

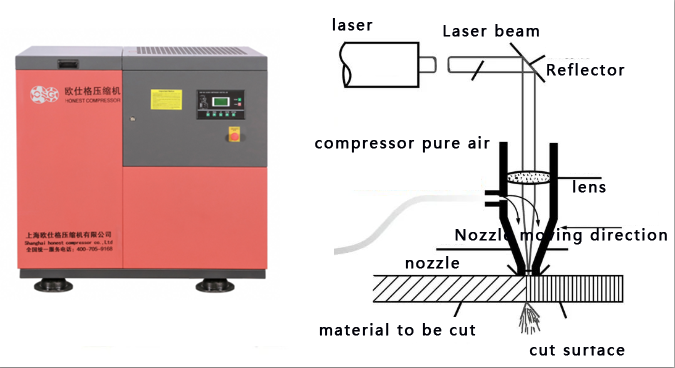

20bar pressure Screw Air Compressor for laser cutting machine

SHORT DESCRIPTION:

Belt trasmission,easy to adjust and replace.

To avoid the orrurrence of air end damage due to any other fault conditions,protect the normal service life of the compressor

Every running state of belt tension reaches to the optimum value.

Greatly extend the working life of the belt and reduce the motor and rotor bearing load by avoiding strarup overlarge tension.

Easy and fast to replace the belt.

20bar high pressure special for laser cutting

High efficiency

Application

Screw air compressors for laser cutting are widely used in sheet metal processing, metal processing, advertising production, kitchen utensils, automobiles, lamps, saw blades, elevators, metal crafts, textile machinery, grain machinery, glasses production, aerospace, medical equipment, Instrumentation and other industries.

Packing

-

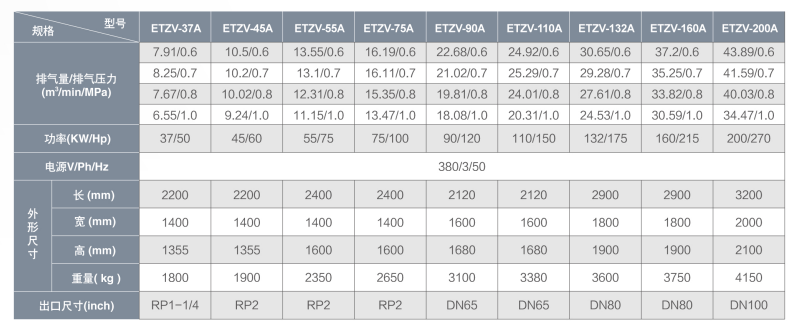

Double permanent magnet motor integrated two-stage compression series

Double permanent magnet motor integrated two-stage compression series

1.Compact size

2. Separate air intake to reduce the load on the cooler

3. Independent installation panel, dual frequency conversion PLC controller

4.Unique air inlet mesh cover, removable and clean dust cover

5.Exhaust fixed pipe clamp to prevent gas shock

Five advantages of host motor

more stable

1.Gearless failure

2.Coupling transmission failure

3. No motor bearing failure

More energy efficient

1.Double permanent magnet motor, stepless speed change

2. Transmission efficiency: 100%

No gear transmission efficiency loss

Loss of coupling transmission efficiency

3.Inter-stage pressure can be adjusted and achieve constant pressure

4. The host is always running at the most energy-saving speed

More efficient

1. High-efficiency permanent magnet motor: IE3

2. Transmission efficiency 100%: integrated shaft structure

3. two air ends and two motors and two inverters

More comfortable

1. The host runs with low noise

2.No gear meshing noise

3. No coupling transmission noise

4.No motor bearing noise

More compact

1.Integral structure, small size

2.Significantly reduce the size of the case

Advantages:

Data sheet for ETZV series

-

10A-PM permanent magnet frequency screw air compressor 220v 50hz single phase

Product classification: permanent magnet frequency screw air compressor

Product Model: XDV-8A

Product power: 1.0m³/min(0.8Mpa)/1.1m³/min(0.7Mpa)