15kw 20hp Air-compressors Screw Rotary Air Compressor / industrial stationary rotary screw air compressor

| Model | XD-15A |

| Free air delivery | 1.9-2.5m3/min |

| Working pressure | 7~12bar |

| Control | automatic PLC controller |

| Driven | direct driven, elastic coupling |

| Starting | star triangle start |

| Cooling | by air |

| Electric motor | 380v/50hz/3ph,IP55 |

| Discharge temperature | less than ambient +8 ℃ |

| Noise | less than 68dB(A) |

| Air outlet size | G3/4” |

| Dimension | 1100*750*920mm |

| Weight | 267kg |

High efficient

* Combined with direct driven arrangement for superior energy efficiency

* Water seals and cools for ideal compression

* Optimal compression processes with the water cooling

Minimum service costs

* Only air filter and water filter need maintenance

* No lubricant costs

* Fast and easy for minimal downtime

High reliability

* Simple and robust design

* Low-speed direct drive, no high speed gears

* Low operating temperatures, no special coatings

High-quality air

* Low air temperature, easy to dry and treat

* No coating on routers that can contaminate or pollute the air

* Class 0 air quality

Environmental safety

* Low noise level

* Reduce energy consumption

* No oil discharge to the environment

(1) Inhalation process:

Motor drive/internal combustion engine rotor, when the tooth groove space of the master and slave rotors turns to the opening of the intake end wall, the space is large, and the outside air is filled in it. The air between the tooth grooves is sealed between the main and slave rotors and the casing to complete the suction process.

(2) Compression process:

At the end of the suction, the closed volume formed by the tooth peaks of the main and slave rotors and the casing decreases with the change of the rotor angle, and moves in a spiral shape, which is the "compression process".

(3) Compressed gas and fuel injection process:

During the transportation process, the volume is continuously reduced, the gas is continuously compressed, the pressure is increased, and the temperature is increased. At the same time, the lubricating oil that has become misty due to the air pressure difference is sprayed into the compression chamber, thereby achieving compression, lowering the temperature, sealing and lubricating. effect.

(4) Exhaust process:

When the closed tooth crest of the rotor rotates to meet the exhaust port of the casing, the compressed air starts to be discharged until the matching surface of the tooth crest and the tooth groove moves to the exhaust end face. gas process. At the same time, another pair of tooth grooves of the main and slave rotors has rotated to the intake end, forming the largest space, and the suction process begins, thus starting a new compression cycle.

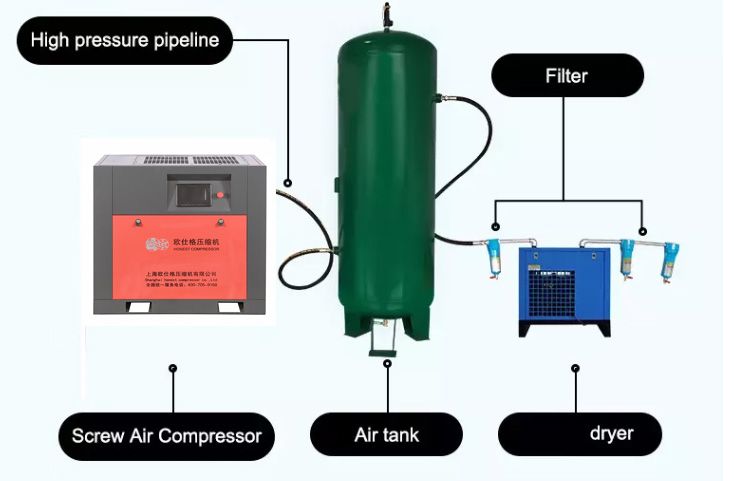

Air compressor > Air tank > Filter > Air dryer > Filters